Test message.

Skip to content

Skip to product information

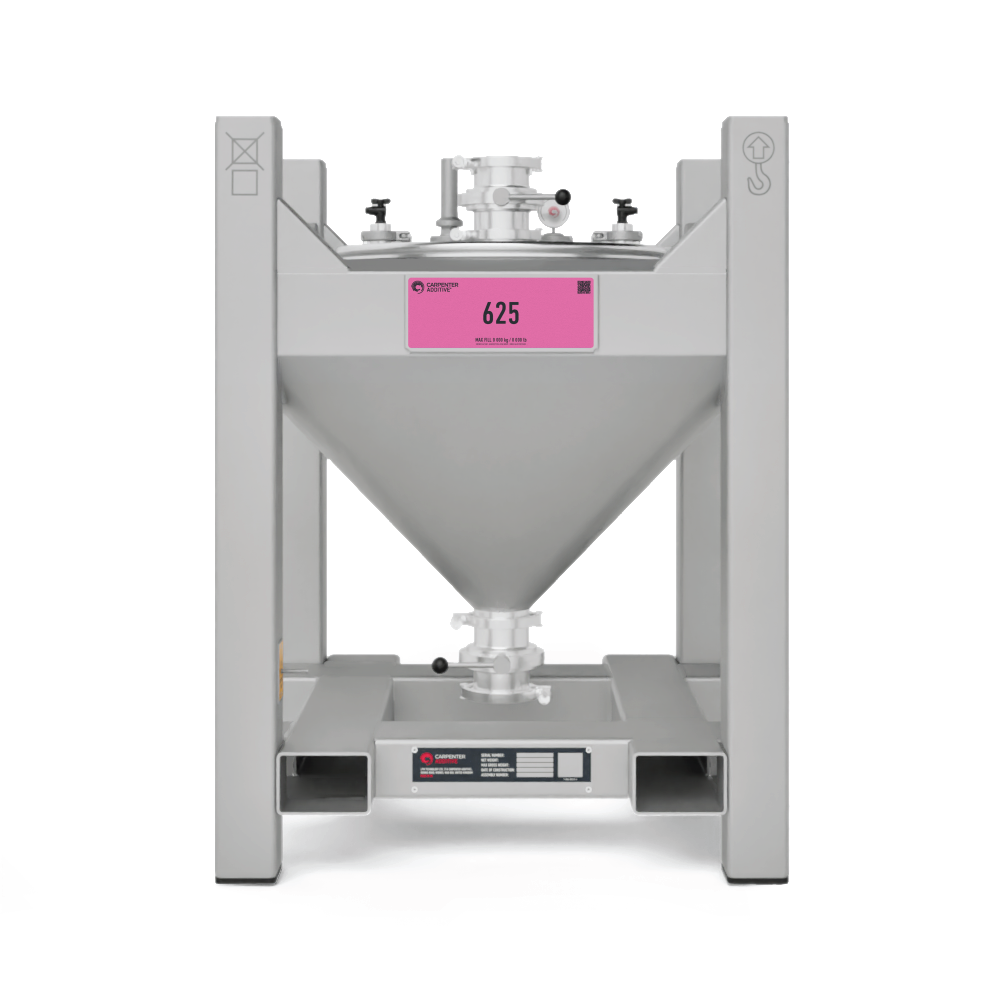

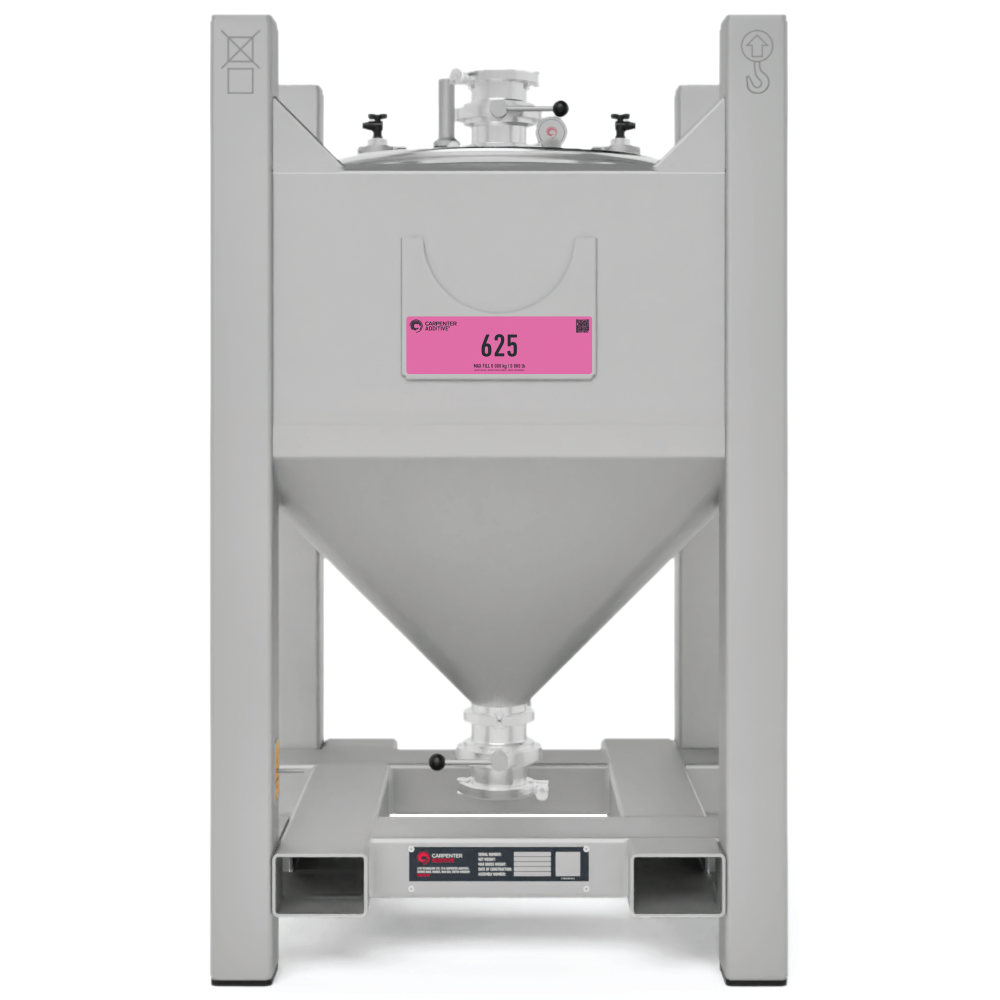

*Images for illustration purposes only

High-Temperature Nickel-Base

PowderRange® 625

Couldn't load pickup availability

Specifications

Machine Type:

F - LPBF

E - EBM

Alternate Names:

Inconel 625, Alloy 625, Nickel 625, Laser Form Ni625, Nickel Alloy IN625, IN625, IN625-0402

PowderRange® 625 is a non-magnetic, corrosion and oxidation resistant, nickel-base superalloy. Its outstanding strength and toughness in the temperature range cryogenic to 2000°F (1093°C) are derived primarily from the solid solution effects of the refractory metals, niobium and molybdenum, in a nickel-chromium matrix.

- Nickel Balance

- Iron 5.00%

- Manganese 0.50%

- Titanium 0.40%

- Nitrogen 0.020%

- Chromium 20.00-23.00%

- Niobium 3.15-4.15%

- Silicon 0.50%

- Nickel Balance

- Carbon 0.10%

- Phosphorus 0.015%

- Molybdenum 8.00-10.00%

- Cobalt 1.00%

- Aluminum 0.40%

- Oxygen 0.030%

- Sulfu 0.015%

Key Properties

- Outstanding strength and toughness in the temperature range cryogenic to 2000°F (1093°C)

- Corrosion and oxidation resistant

- Non-magnetic

Markets:

- Aerospace

- Automotive

- Marine

Applications:

- Heat shields

- Furnace hardware

- Combustion liners and spray bars

- Gas turbine engine ducting

- Chemical plant hardware

- Special marine and seawater applications

- Choosing a selection results in a full page refresh.