Test message.

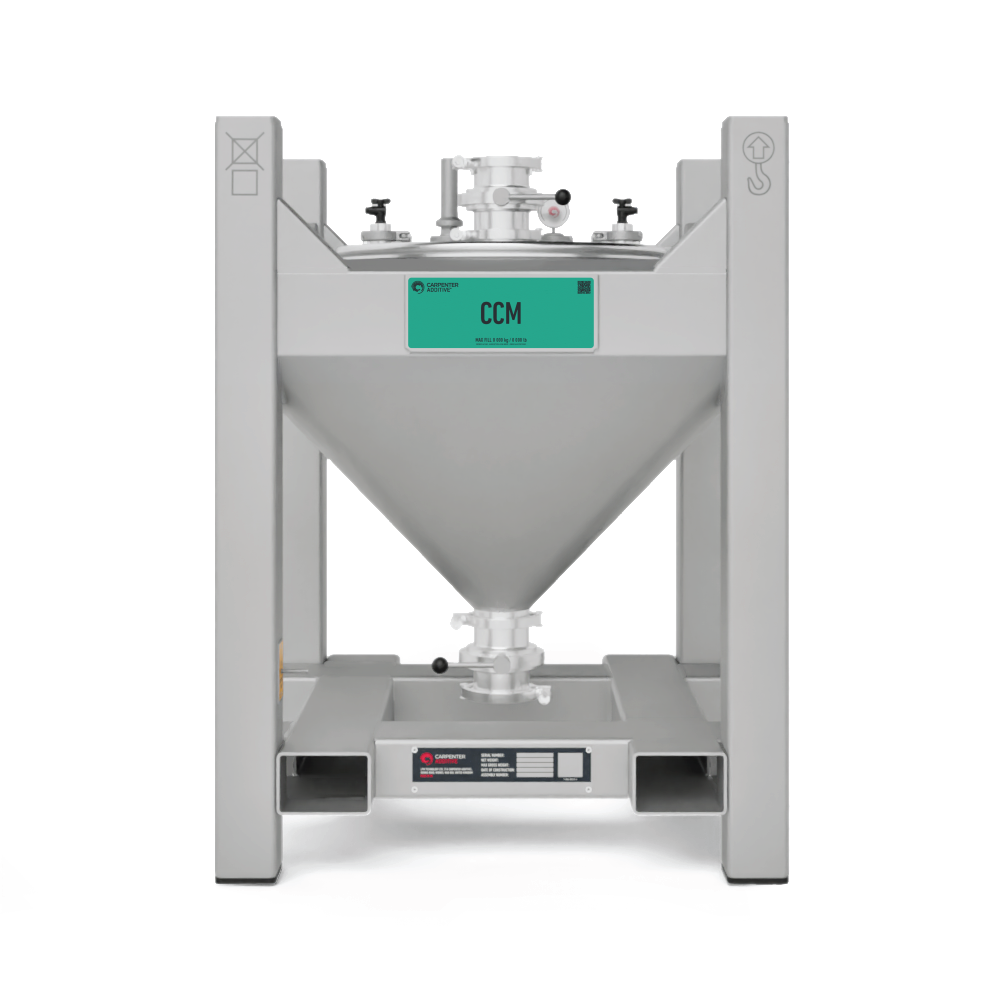

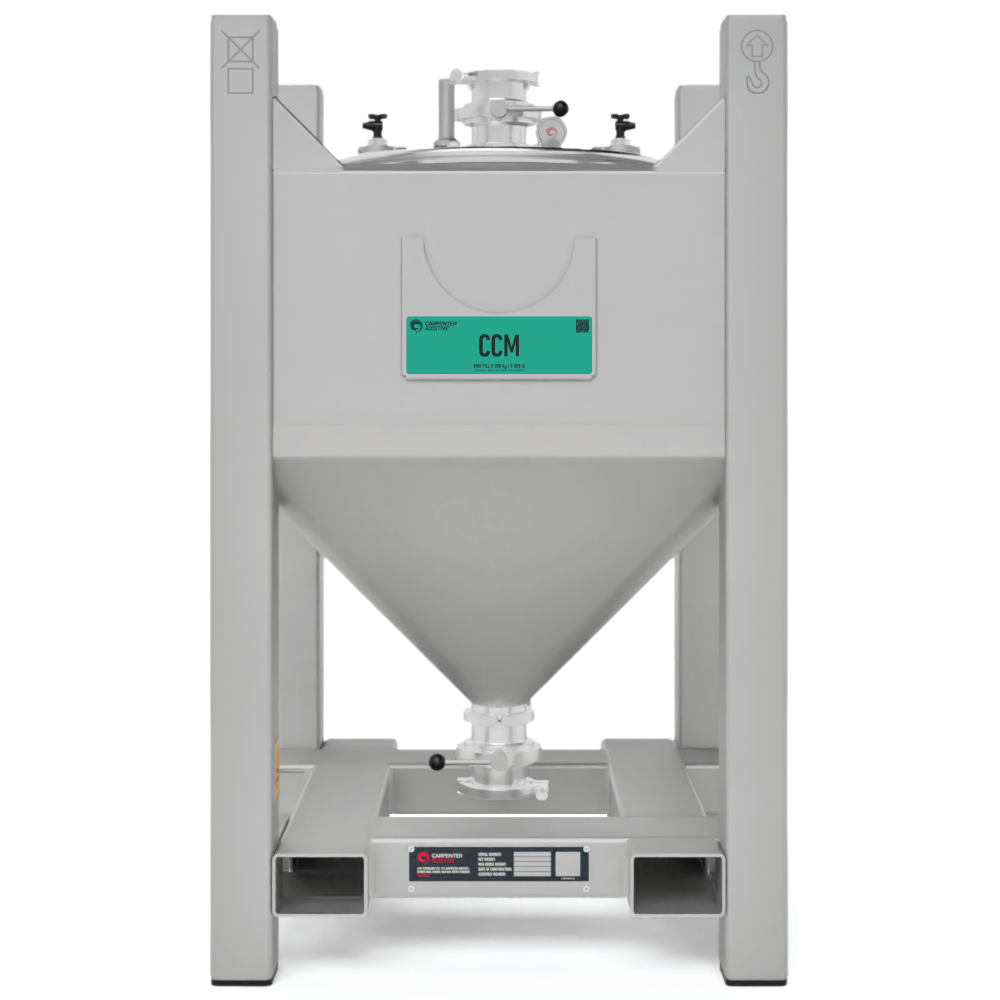

*Images for illustration purposes only

Cobalt-Base

PowderRange® CCM

Couldn't load pickup availability

Specifications

PowderRange® CCM is a non-magnetic, cobalt-chromium molybdenum alloy exhibiting high strength, corrosion resistance, wear resistance, and excellent biocompatibility. This alloy meets the low carbon wrought version of ASTM F 75 Cast Alloy.

PowderRange® CCM powder is produced by vacuum induction melting (VIM) followed by nitrogen gas atomization. It has excellent weldability in laser additive manufacturing processes and can be processed with either nitrogen or argon shielding gas.

PowderRange® CCM exhibits high strength up to 1112 °F (600 °C) and maintains mechanical properties under a variety of corrosive environments. When specified with nickel content below 0.1%, PowderRange® CCM is biocompatible. It can also be used in Magnetic Resonance Imaging (MRI) equipment, as it is non-magnetic.

These properties make PowderRange® CCM ideal for small biomedical devices where high strength and fatigue resistance are required.

- Cobalt Balance

- Manganese 1.00%

- Nickel 0.50%

- Aluminum 0.10%

- Titanium 0.10%

- Sulfur 0.010%

- Chromium 27.00 - 30.00%

- Silicon 1.00%

- Nitrogen 0.25%

- Cobalt Balance

- Carbon 0.10%

- Phosphorus 0.020%

- Molybdenum 5.00 - 7.00%

- Iron 0.75%

- Tungsten 0.20%

- Oxygen 0.10%

- Boron 0.010%

Key Properties

- High strength to 1112°F (600°C)

- Wear and erosion resistant

- Biocompatible and non-magnetic — suited for small biomedical devices

Markets:

- Energy

- Medical

Applications:

- Orthopedic and dental implants

- Medical fracture fixation devices

- Gas turbine nozzle and instrumentation devices

- Oil and gas tooling and instrumentation

- Choosing a selection results in a full page refresh.