Test message.

A Powder-to-part Closed LoopAm Ecosystem

Hardware, software, and processes to drive innovation

Manage Risk, Enhance Safety and Optimize Economics with PowderLife

Integration, data management, material contamination and quality, or powder reuse and traceability are all barriers to success of serial production additive manufacturing. Driving innovative, partner-focused solutions, Carpenter Additive works in cooperation with customers to offer powder management and handling solutions specifically tailored to individual AM processes and facilities.

Operational considerations yield improvement in productivity and overall equipment effectiveness, material waste reduction, and environmental health and safety mitigation with large-scale powder usage. Carpenter Additive’s PowderLife was developed specifically with advanced AM users in mind looking to achieve a series of gains from their AM production program to drive sustainable improvements. The PowderLife solutions portfolio includes

Material advisory services

Safe powder handling hardware for industry operators

Mitigated powder exposure risk through smart bulk transportation

Data used to drive smart decisions during the AM process

Extended powder reuse quantified through data analytics

Material optimized to deliver maximum economics

Add Confidence, Reliability and Traceability to the AM Value Chain

Powder Management

The Hopper

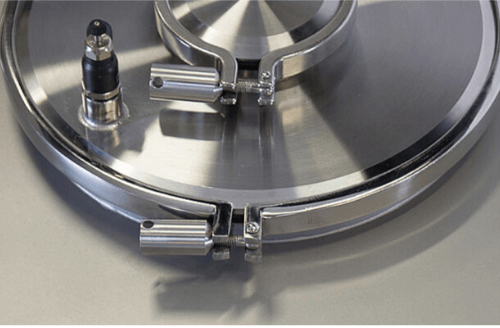

Carpenter Additive hoppers are the smart solution to the bulk transportation and storage challenges of metal powders for AM. These ergonomic stainless-steel hoppers enable the safe transportation of large amounts of powder, minimizing the risk of material contamination and enabling customers to concentrate on producing parts with reliability and peace of mind. Providing a closed-loop solution, from point of atomization to the loading of the AM machine.

Purpose-designed exclusively for AM metal powders, Carpenter Additive hoppers have a material capacity of up to 850 kg. The hoppers are designed to allow powder to be transported under inert conditions, ensuring the materials stay free from gaseous contaminants such as oxygen and nitrogen and other foreign bodies – critical, as contamination can lead to failed builds and can affect the final mechanical properties of built parts.

Hoppers are designed and clearly labelled to be alloy specific with the option of a unique QR code to link to the optional software, to monitor and control traceability and manage inventory.

A complimentary range of Carpenter Additive’s products and adaptors allow for the hopper to be seamlessly integrated into your AM value chain.

As the world becomes more environmentally conscientious, it’s important to reflect, how conscientious is your business?

Typically, in the AM industry, powder is received in plastic containers, resulting in approximately 17kg of plastic waste for 450kg of powder in an AM build. Carpenter Additive can support businesses on their journey to improve the environment with the environmentally friendly, bulk transportation solution. The hopper is reusable, recyclable and easy to clean.

How We Can HelpPowderflow

PowderFlow enables the user to understand their powders and processes further through the measurement of flow of powder. The results enable the end user to determine if their powder will spread effectively throughout the build process in the AM machine.

A portable kit, PowderFlow enables the user to check powder flowability wherever and whenever it’s required. Gain a deeper understanding of powder and be confident in the quality of final build parts.

How We Can HelpSoftware Solutions

Managing the Full Powder Value Stream. Simply.

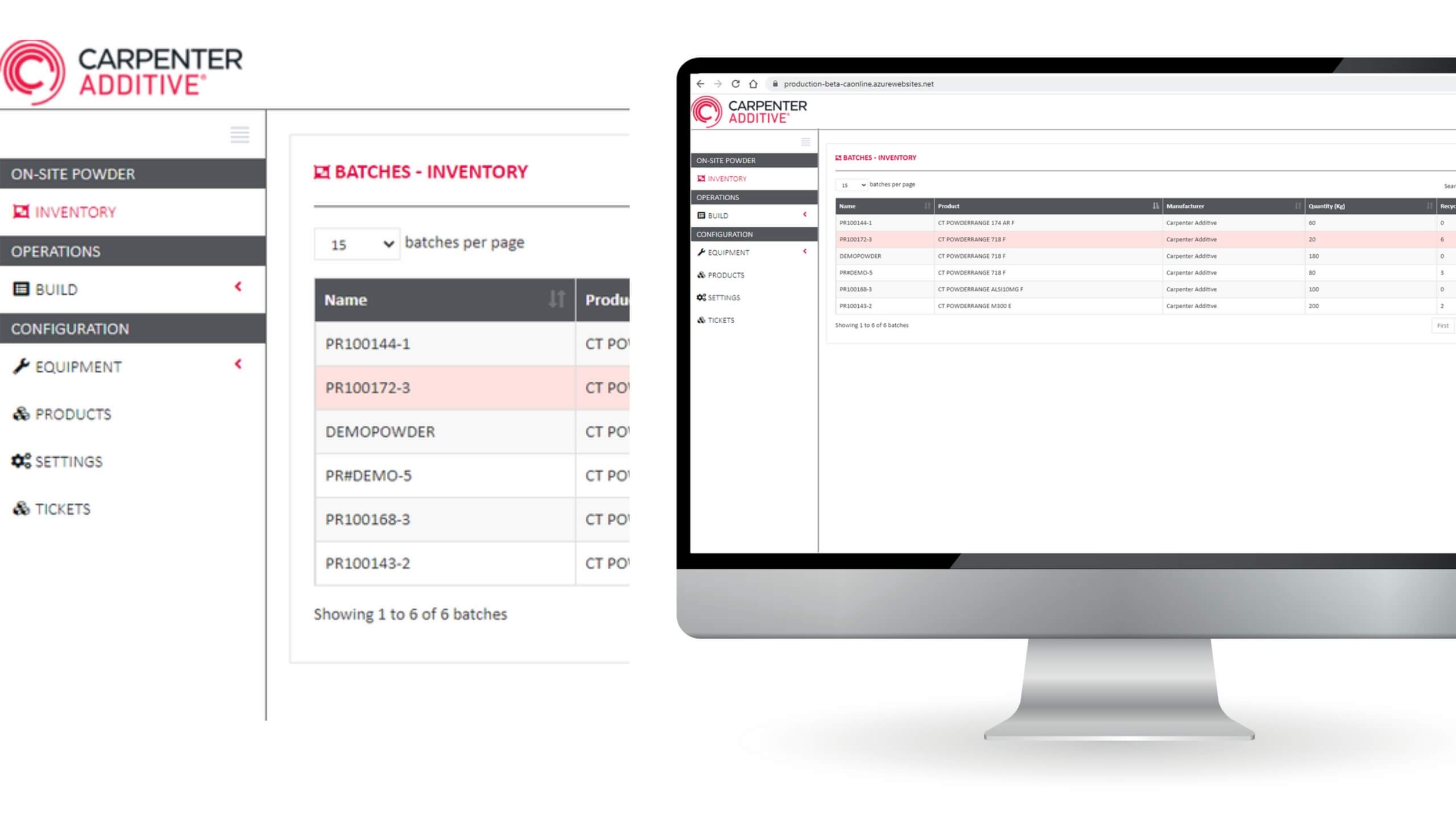

Barriers to additive manufacturing industrialization include powder quality and reusability, material handling, and inventory management. Today, these challenges around metal powder are managed through a plurality of systems for tracking inventory with individually populated spreadsheets and paper certificates. These various manual steps increase inefficiencies and offer neither a digital connection for automated traceability throughout the complete process chain nor output data for future predictive analytics.

PowderLife ONLINE from Carpenter Additive aims to address these challenges through a simple to use, secure, cloud-based, digital platform that accommodates materials and machines from all vendors. Serving as the foundation to the AM process, PowderLife ONLINE is a single system designed to govern the entire AM process with the ability to capture the digital thread, and fulfil regulatory requirements to provide documentation for powder reuse, offering a single point of truth for traceability and inventory management throughout the entire lifecycle of the powder.

The PowderLife ONLINE platform acts as the starting block for the digitization journey to integrate other Carpenter Additive digitally-enabled products and software modules such as IoT sensors, RFID, & automation to add further value and drive intelligent decision making, improving economics by taking away the 'best guess' for powder reuse limits and unlocking the potential for further data-driven continuous improvement activities, providing manufacturers with the assurance of the performance and quality of their additive parts together with the confidence of traceability to meet industry requirements.

View full T&C's here Register TodayProcess Contultantions And Lab

Testing Services

Process Consultations and Lab Testing Services

Carpenter Additive’s industry-leading technicians are on hand to carry out a variety of metal powder tests. Add peace of mind to your AM processes with a full suite of professional powder lab testing services. Offering a range of chemical and physical metal powder analysis techniques across our world-class powder testing facilities, Carpenter Additive is skilled in interpreting powder data. All tests are conducted to ASTM as standard, with ISO available on request.

Full chemical analysis is available including residual elements and interstitials using various techniques as appropriate, undertaken in an ISO17025/Nadcap approved laboratory.

- Oxygen, nitrogen, and hydrogen analysis by Inert Gas Fusion

- Elemental analysis/contamination screening (EDX)

- Chemistry- Full chemical analysis by ICP

- Moisture analysis by Karl Fischer titration A range of physical testing services is also available.

- Apparent/bulk density (measurement according to ASTM B212)

- Tap density (ASTM B527)

- Hall flow (ASTM B213) Carney flow (ASTM B964)

- The angle of repose (Carpenter Additive standardized internal procedure)

- A sieve analysis (ASTM B214)

- Particle size distribution by Laser Size Diffraction (ASTM B822)

- Powder imaging (SEM)

- Powder cross-section/porosity imaging (SEM)

- Metallographic sample preparation & examination (SEM)

- Rheometry and shear cell analysis

- True density by helium gas pycnometer (ASTM B923)

- Quantitative shape analysis (Optical & SEM)

Metal Powder to Deliver Mechanical Properties Tailored to Precise Applications

Not every project is standard. Beyond our PowderRange in-stock offerings, we can size powders and produce materials to meet individual specifications. From a single metal powder test to new alloy development, our experts design and develop novel metal alloys, atomized in-house, in partnership with you.

- Choosing a selection results in a full page refresh.