Test message.

Skip to content

Skip to product information

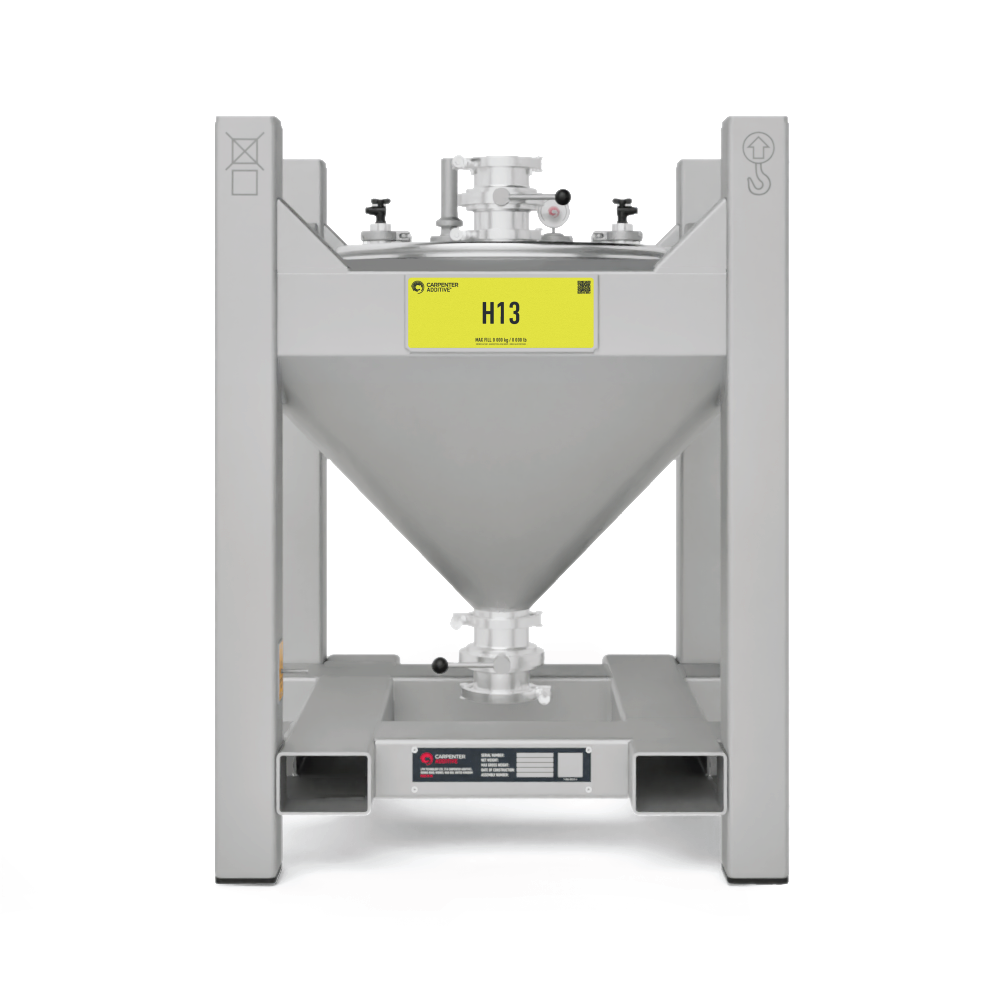

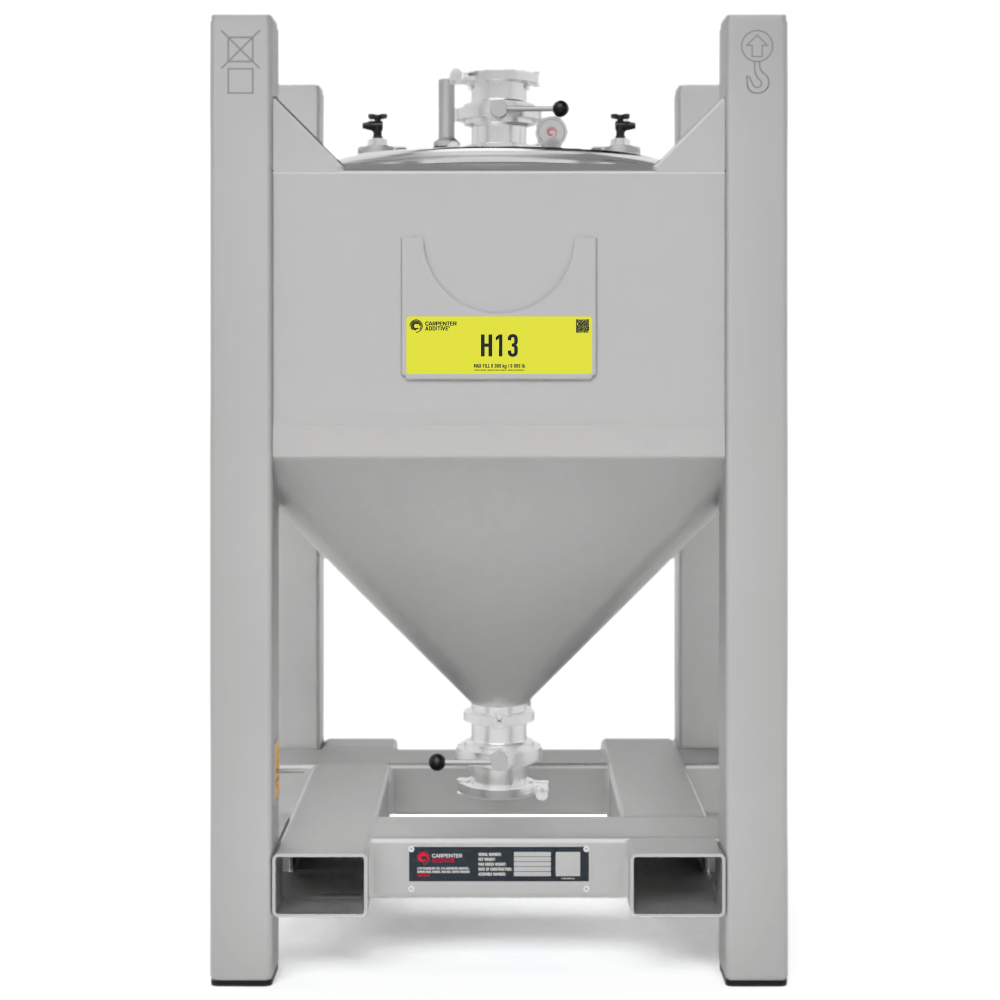

*Images for illustration purposes only

Tool & Die Steel Iron-Base

PowderRange® H13

Couldn't load pickup availability

Specifications

PowderRange® H13 is a versatile air hardening, 5% chromium hot work steel. It exhibits a good combination of high toughness, temper resistance, and thermal fatigue resistance.

PowderRange® H13 has challenging weldability in laser and electron-beam additive manufacturing processes, where part geometry and build parameters could induce micro-cracking.

- Iron Balance

- Chromium 4.80 – 5.50 %

- Molybdenum 1.10 – 1.50 %

- Silicon 0.80 – 1.20 %

- Vanadium 0.80 – 1.15 %

- Carbon 0.35 – 0.42 %

- Iron Balance

- Manganese 0.25 – 0.50 %

- Nitrogen 0.10 %

- Oxygen 0.10 %

- Phosphorus 0.03 %

- Sulfur 0.02 %

Key Properties

- High impact toughness and good ductility

- High temperature strength

- Good abrasion resistance at temperature

- Resistance to thermal fatigue

- Limited distortion during hardening

Markets:

- Energy

- Industrial

Applications:

- Tooling for extrusion and molding

- Valves and fittings

- Pumps and impellers

- Manifolds

- Die casting

- Choosing a selection results in a full page refresh.