Test message.

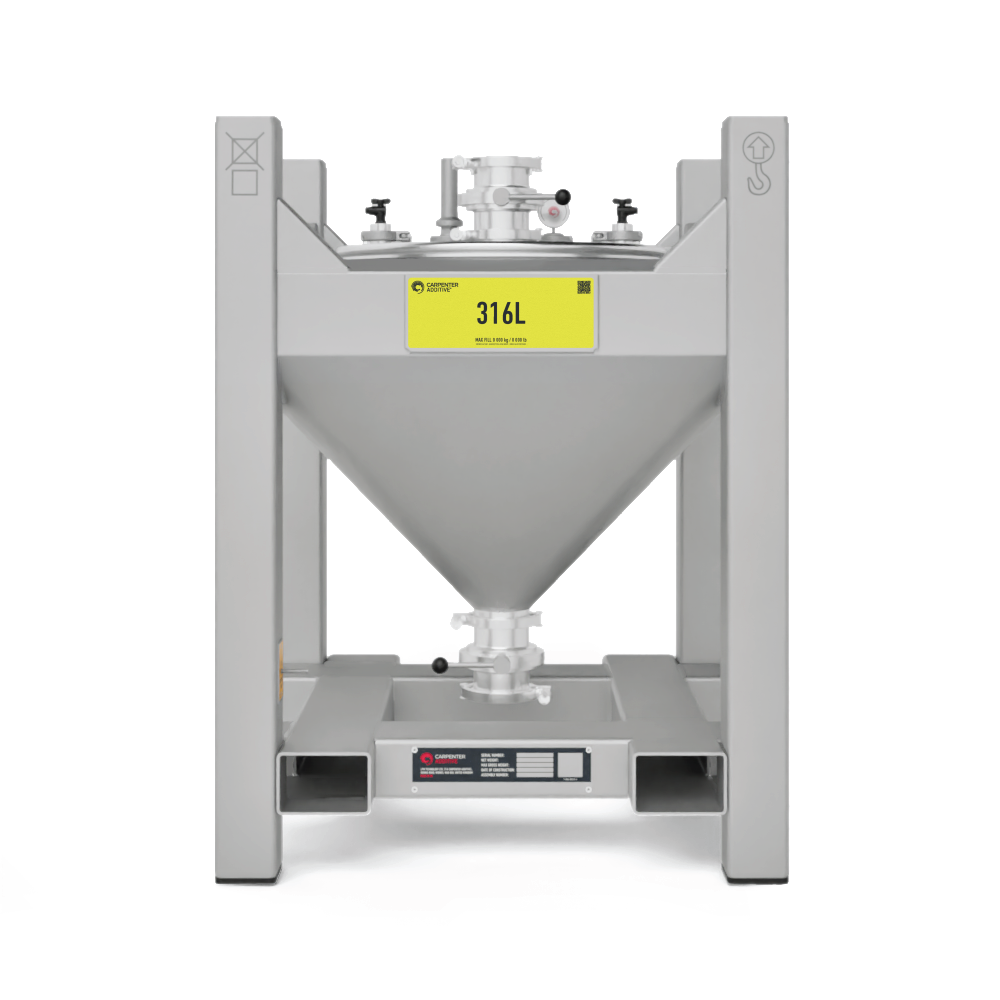

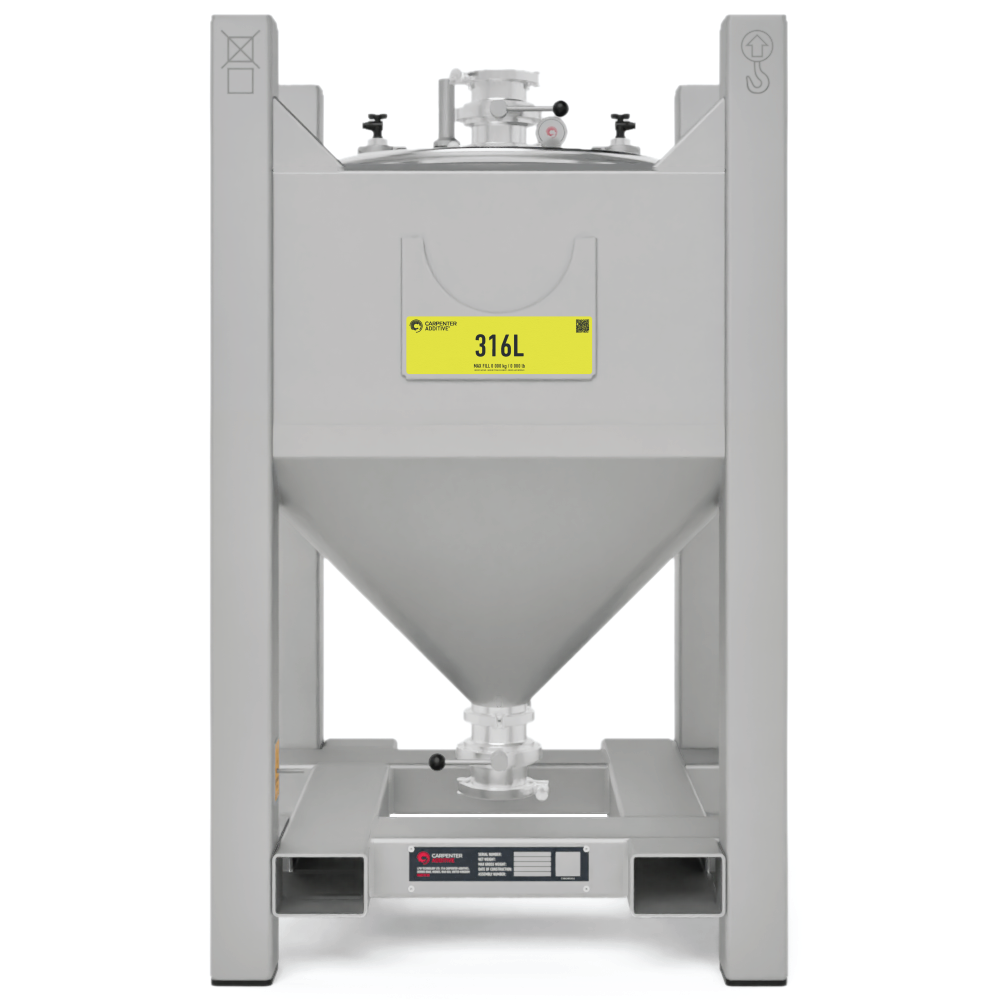

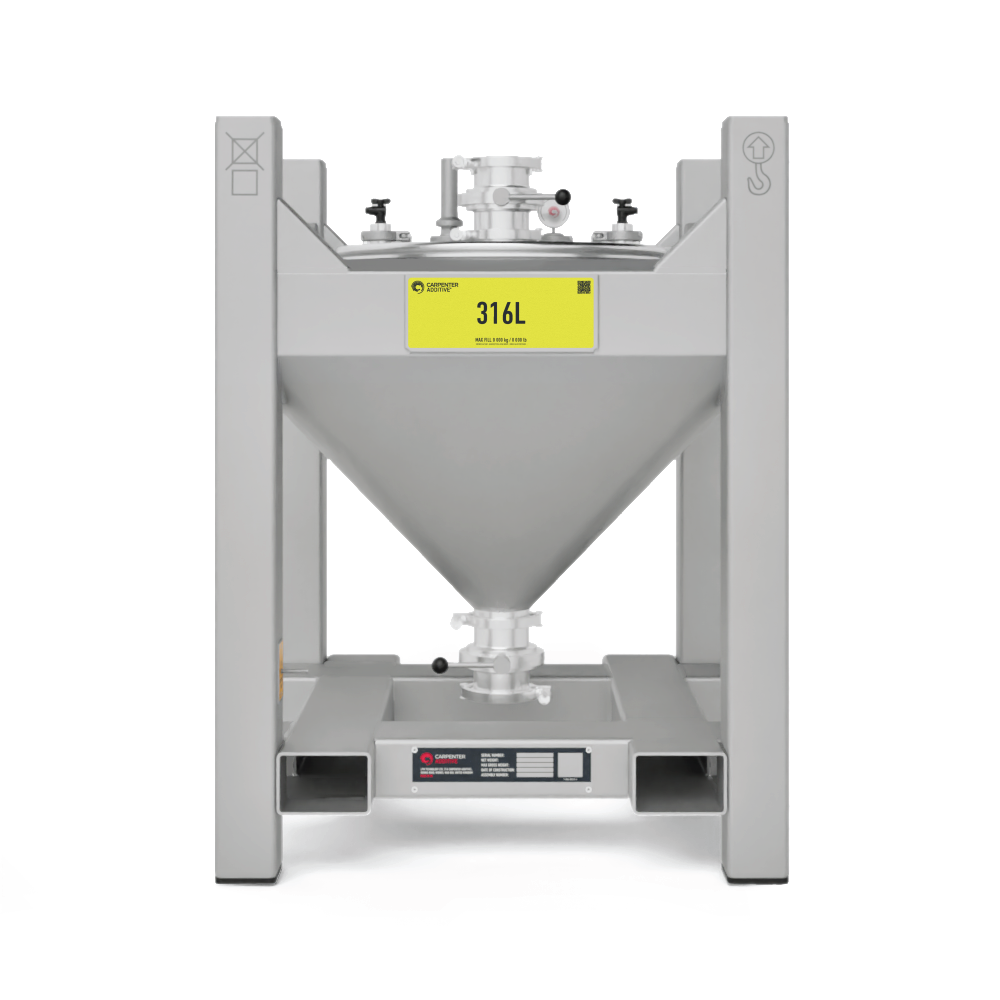

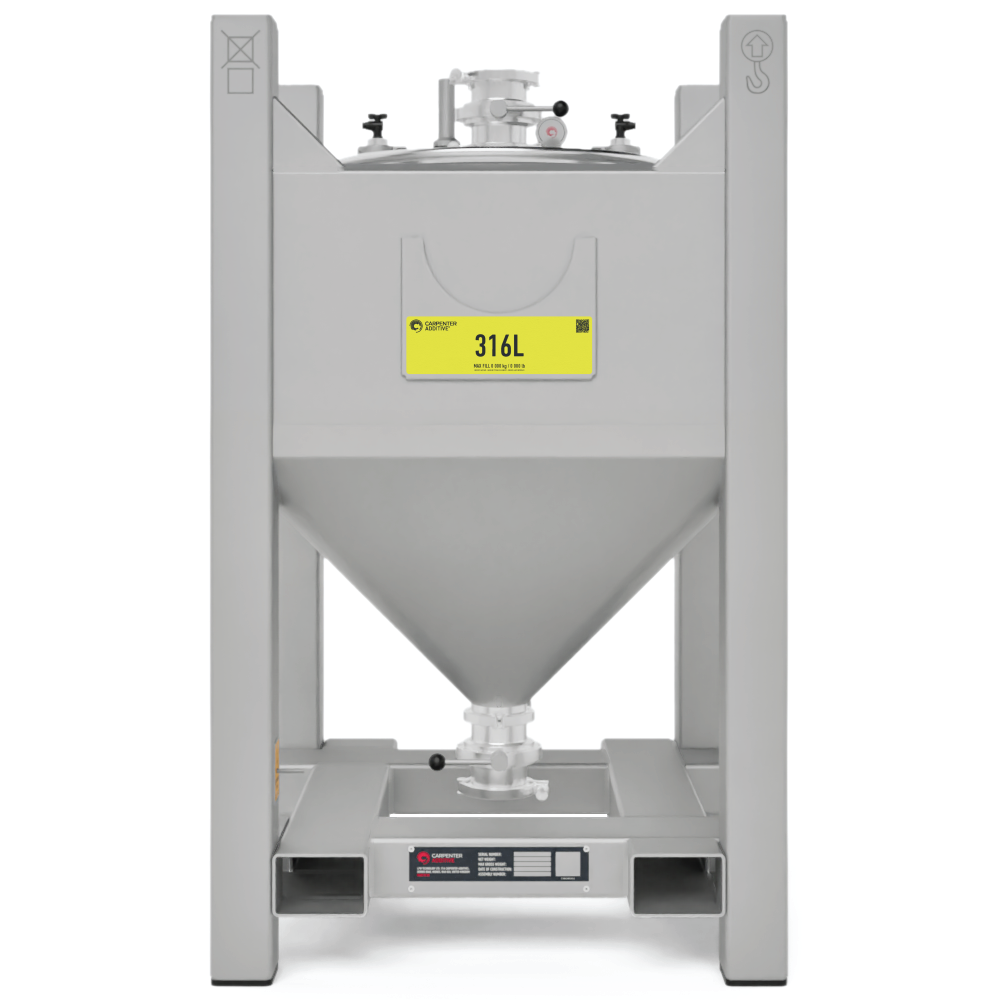

*Images for illustration purposes only

Stainless Steel Iron-Base

PowderRange® 316L

Couldn't load pickup availability

Specifications

Machine Type:

F - LPBF

E - EBM, DED

Alternate Names:

1.4404, 316L, LaserForm 316L, SS 316L-0407

PowderRange® 316L is a low carbon, non-magnetic, austenitic stainless steel that exhibits moderate to good strength, good fracture toughness, and has generally good corrosion resistance, especially intergranular corrosion. It has excellent weldability in laser and electron-beam additive manufacturing processes and can be processed in either argon or nitrogen shielding gas.

PowderRange® 316L cannot be strengthened through post processing heat treatments but can be solution annealed to improve corrosion resistance. Solution annealing is application-specific, but is generally not necessary for most situations. Post processing can include traditional machining, abrasive flow machining, shot-peening, grinding, polishing, chemical milling/etching, and other methods.

- Iron Balance

- Chromium 16.0 – 18.0 %

- Nickel 10.0 – 14.0 %

- Molybdenum 2.00 – 3.00 %

- Manganese 2.00 %

- Silicon 1.00 %

- Iron Balance

- Nitrogen 0.10 %

- Oxygen 0.10 %

- Phosphorus 0.045 %

- Carbon 0.030 %

- Sulfur 0.030 %

Key Properties

- High impact toughness and good ductility

- Moderate strength and creep resistance

- Good corrosion resistance

Markets:

- Aerospace

- Transportation

- Medical

Applications:

- Instrumentation devices

- Valves and fittings

- Pumps and impellers

- Manifolds

- Medical implants

- Tooling

- Choosing a selection results in a full page refresh.