Test message.

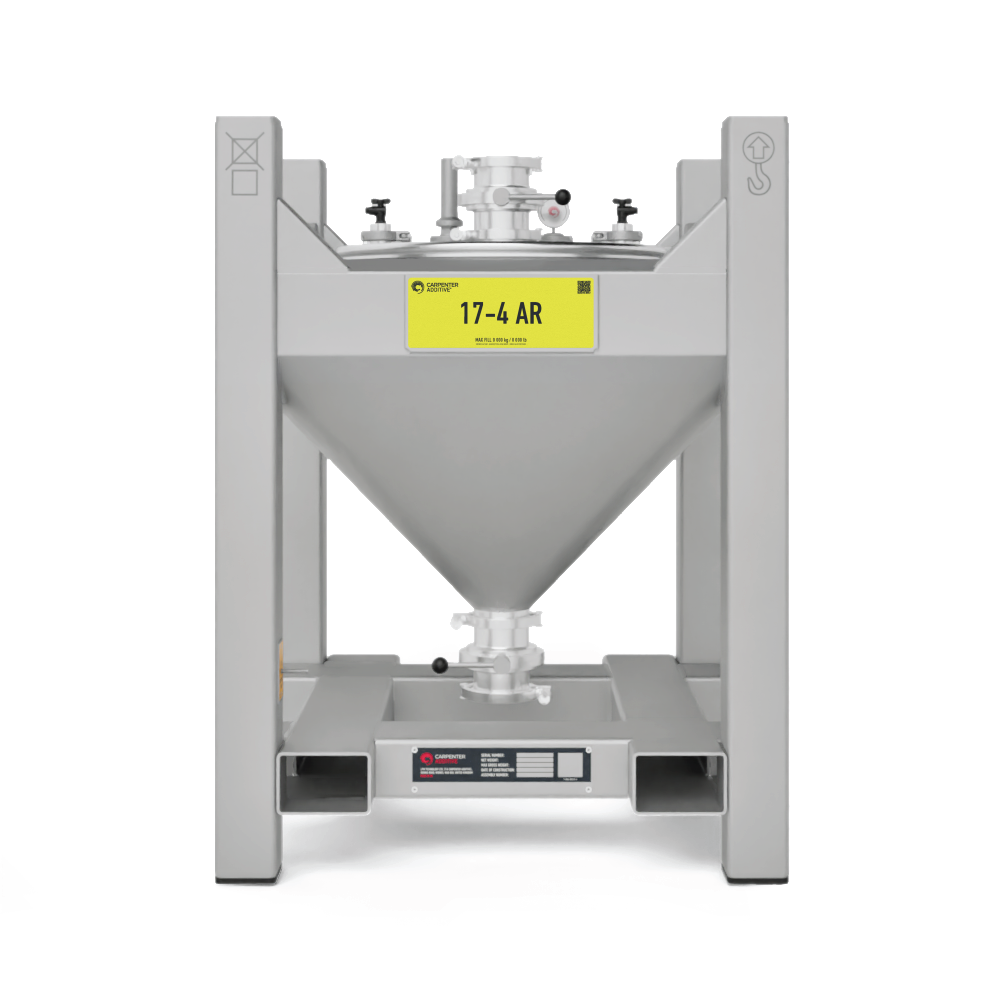

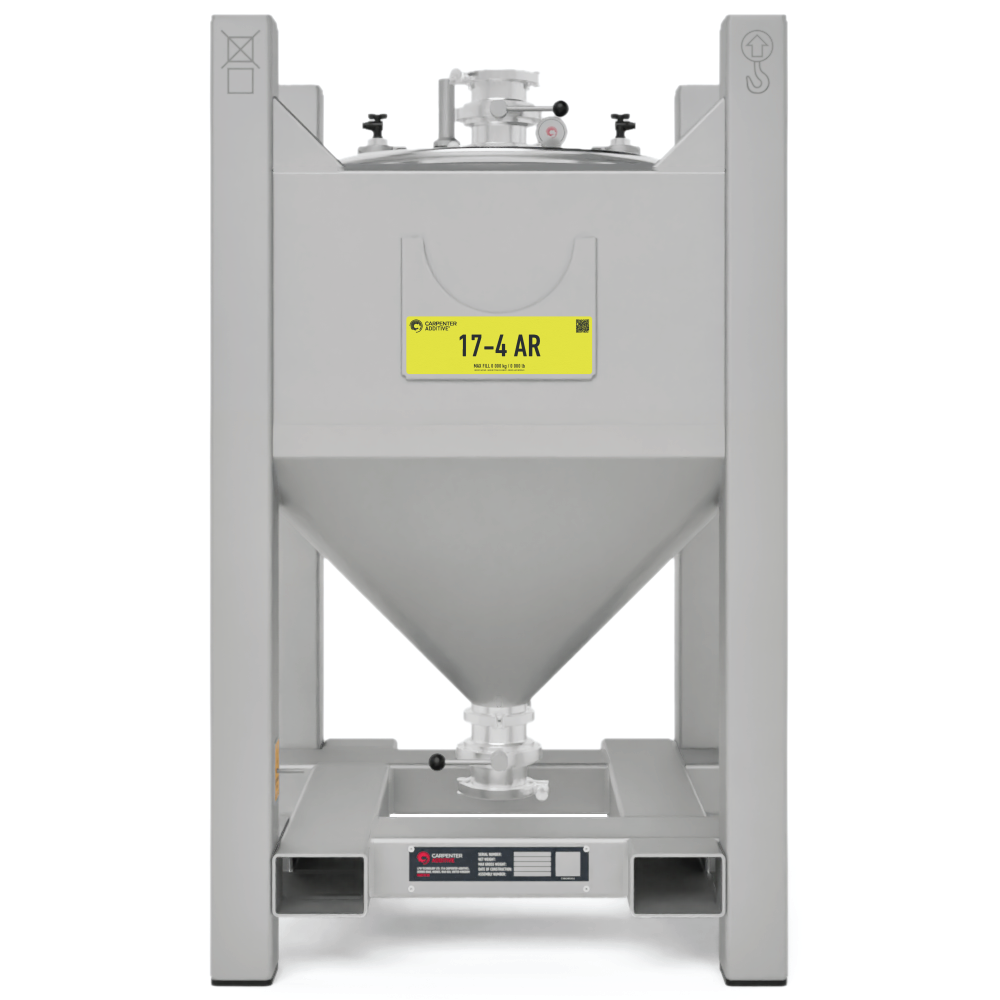

*Images for illustration purposes only

Stainless Steel Iron-Base

PowderRange® 17-4 AR

Couldn't load pickup availability

Specifications

Similar Materials:

PowderRange 174PH

Machine Type:

F - LPBF

Alternate Names:

1.4542, 17-4PH, LaserForm 17-4PH, GP1, Stainless Steel 17-4

PowderRange® 17-4 AR stainless steel is a martensitic precipitation/age-hardening stainless-steel offering high strength and hardness, along with excellent corrosion resistance, up to 600°F (316°C). It has good fabricating characteristics and can be age-hardened by a single-step, low-temperature treatment, which can be chosen to achieve specific strength and toughness combinations.

Due to this balanced combination of performance and ease of use in AM, PowderRange® 17-4 AR for additive manufacturing has been used for a wide variety of applications, including rapid tooling functional components in nearly every market, and prototyping.

- Iron Balance

- Chromium 15.00–17.50 %

- Copper 3.00–5.00 %

- Nickel 3.00–5.00 %

- Manganese 1.00 %

- Silicon 1.00 %

- Molybdenum 0.50 %

- Niobium + Tantalum /span> 0.15 –0.45 %

- Iron Balance

- Cobalt 0.40 %

- Carbon 0.07 % max

- Aluminum 0.05 % max

- Oxygen 0.10 % max

- Phosphorus 0.040 %

- Nitrogen 0.030 %

- Sulfur 0.030 %

- Tin 0.02 % max

Key Properties

- Good strength, toughness, hardness, and ductility

- Good corrosion resistance

Markets:

- Aerospace

- Food processing

- Petrochemical

- Medical

Applications:

- Surgical instruments and tools

- Valves and fittings

- Pumps and impellers

- Manifolds

- Industrial and chemical processing equipment

- Tooling

- Choosing a selection results in a full page refresh.